Materials that matter: Manteco

Meet the family-run luxury fabric makers, textile innovators and long-time COS collaborators redefining the future of fabrics — and our industry.

The year is 1941. Europe is at war and textile production is at an all-time low. Yet, in a small town in the north of Italy Enzo Anacleto Mantellassi acquires a bombed-out spinning mill and starts producing recycled wool yarns from old military garments and covers – not realising he was changing the way clothing could be made for the better.

Fast forward to 2021 and Manteco, now managed by Enzo’s son Franco Mantellassi and grandsons Matteo and Marco, are a leading company renowned worldwide for their high-end fabrics and – unsurprisingly – sustainable production solutions. ‘[Keeping the business in the family] has been fundamental for our success,’ explains CEO Marco Mantellassi (he/him). ‘It has allowed us to maintain a common thread during the entire life of the company with the same philosophy and values as our predecessors.’

With quality and sustainability making up the very fabric of their being, it’s no surprise that they’ve had a long-standing relationship with COS since the brand began in 2007. What started out as a desire to create the finest quality clothing is now a joint venture in sustainable innovation – with both brands pushing the boundaries of how fashion can be made in a more responsible way. ‘The relationship we have with COS is much more than just trade, it has evolved to be an inspirational co-branding partnership’ explains Marco. ‘Thanks to investments and constant research we have managed to get ahead of the times and offer products that are locally produced, high-quality, sustainable and – most of the time – recyclable’.

Taking one step closer towards their goal of having a 100% sustainably made collection (currently, as of 2021, it’s 86%), COS have invested in four new fabric innovations by Manteco for their AW21 collection – each one more sustainably sourced. To find out more, we got into the details with the man from Manteco himself, Marco Mantellassi...

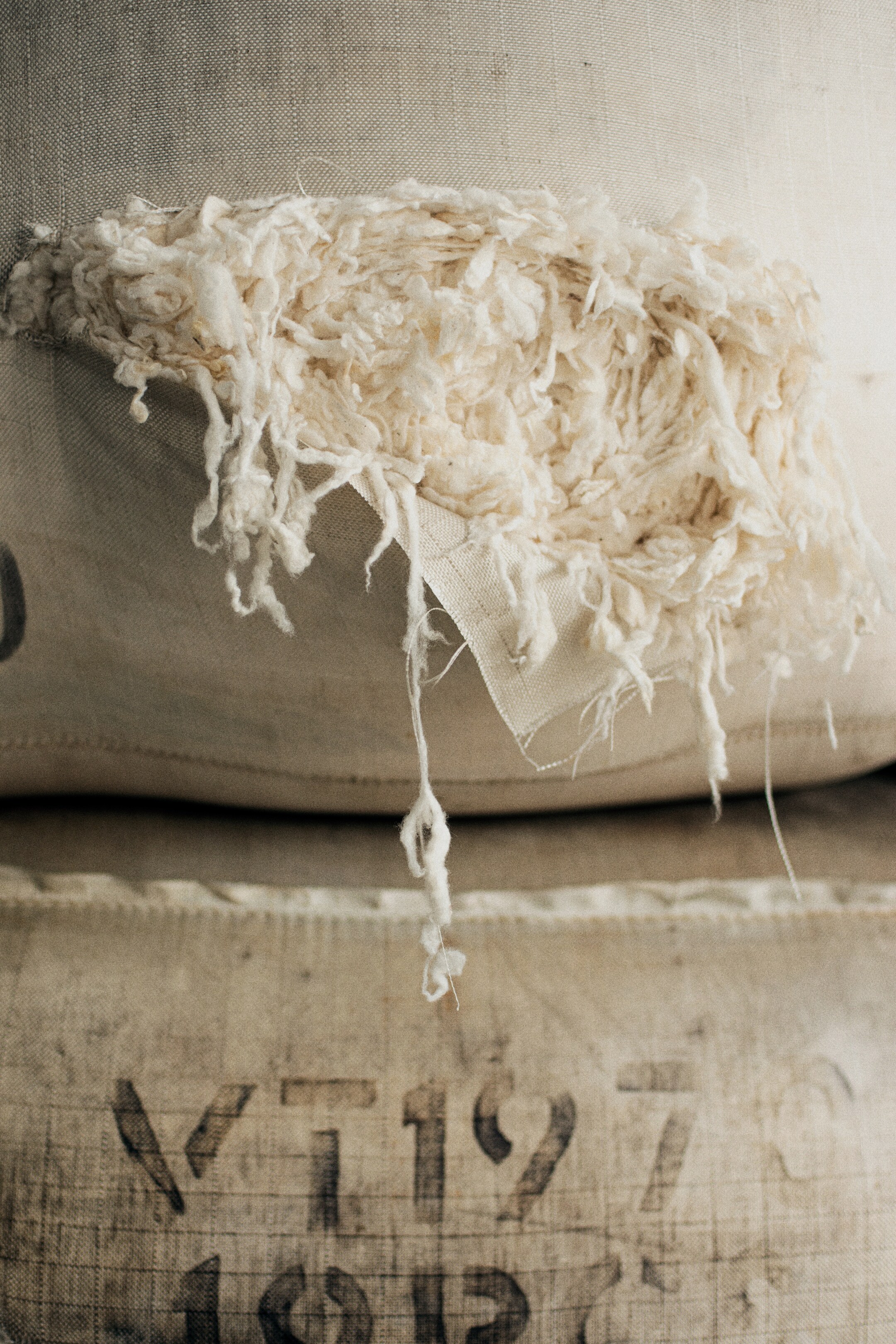

Archivio Manteco, Prato, Italy, (Image: courtesy of Archivio Manteco).

Archivio Manteco, Prato, Italy, (Image: courtesy of Archivio Manteco).

ON MANTECO’S SECRET TO SUCCESS

‘Striving for improvement is a company philosophy, so we constantly brainstorm with the material, design and production teams to spot anything we can enhance.’

‘Our secret is the supply chain we have created over the years. We have selected the best mills and artisans in the Prato district, near Florence. Making fabrics in Italy is special because we – as a population – have done this job for centuries, accumulating know-how and passing it on to younger generations. This has led ‘made in Italy’ to be what it is today: a guarantee of quality and excellence. All our partner mills are within 10 miles of our headquarters and are visited daily by our team to check quality and production progress.’

‘We take a 360° approach. First, we make sure that most of our fabrics are recyclable at the end of their life. In addition to this, we use recycled raw materials – like recycled wool (MWool®). This is made by recovering all our leftovers through a zero-waste system – saving at least 10% of the wool we process every year. In addition to this, we create colours with no dyes through the Recype® process and take care of garment-making offcuts through Project43 and Project53 – two traceable circular economy projects that can help brands save 10%–20% of fabric from going to waste.’

ON COLLABORATING – AND INNOVATING – WITH COS

‘We are proud of our long-lasting relationship with COS. Thanks to our collaborations over the years, we have made many improvements on our products. We’re also a great example of transparency, showing the fashion world that co-brandings can give even more value to clothing.’

‘Our new fabric innovations in COS’ AW21 collection are the result of constant research on special fibres and finishings. They are all types of wool and made in Italy in a zero-mile supply chain – securing both high quality and low environmental impact.’

‘In addition to their appeal from a sustainability point of view, they all have slightly different qualities that gives each one its own unique character. For example, one is a type of boiled wool fabric that’s extremely lightweight and has a washed finish to give it that rustic, worn-in feel – without it physically being worn.’

ON THE FUTURE OF MANTECO FABRICS

‘Our goal is to have a collection that is more and more sustainable. Manteco is already a well-known textile supplier, but we would like people to look to us as a symbol of quality, sustainability and durability. We are working hard on an even more measured and efficient circularity, through extended Life Cycle Assessments, zero-waste production systems and take-back programs. Our ultimate ambition is to become a leader for sustainable and luxurious fabrics.’

Images courtesy of Archivio Manteco.